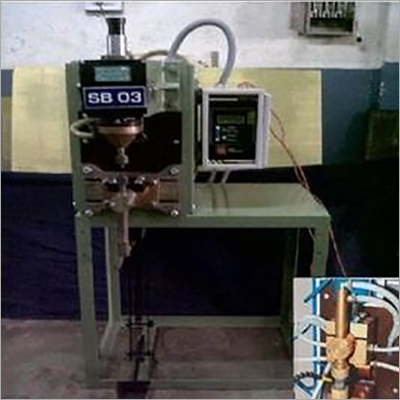

Bench Type Spot Welding Machine

Product Details:

Product Description

MACHINE BODY: This consists of a rugged mild steel fabricated frame on which is mounted the movable upper electrode assembly, lower horn assembly and pedal mechanism assembly.

WELDING TRANSFORMER: Special design technique adopted offers maximum efficiency of the transformer. Sandwitch construction of coils help to increase the coupling between the windings. Primary and secondary conductors are selected to suit the heavy demand current. Vertically rolled electrolytic copper bus bar is used as secondary. Transformer core is made out of cold rolled grain oriented lamination sheets, to reduce the core losses. Class F insulation materials used in the transformer helps to withstand a temperature of upto 155oC. The cold assembly is varnished in F50 varnish and vacuum impregnated.

ELECTRODE HOLDER AND ELECTRODE SYSTEM: The upper electrode as well as lower electrode is water cooled. Also the electrode holder is water cooled. The press type ram system is practically friction free rapid follow up for precision welding 'C' type slotted face plate is provided at the bottom of the lower arm holder assembly to facilitate electrode alignment with respect to the upper elec trode> Lower arm or horm is clamped in a heavy bracket which is adjustable in the horizontal plane. The holder is also adjustable in and out and may be rotated through 360o on its axis.

PRESSURE ADJUSTING MECHANISM : The forging force applied to the work piece is adjustable with the help of a knob provided at the top of the ram. When the knob rotates clockwise the pressure increases and the pressure decreases when it is rotated anticlockwise. Pressure can be adjusted from 10 Kgs to 150 Kgs. Standard electrode, plain and tipped are available from stock. Electrodes are made out of special chromium copper alloy and heat treated to a hardness of Rockwell B scale 70 - 80.

PNEUMATIC SYSTEM : The basic pneumatic system consists of a pneumatic double acting cylinder, solenoid valve of 4 way 5 port, filter, lubricator, regulator, gauge and foot operating initiating switch for solenoid coil. The precision honed and lapped pneumatic cylinder, both sides cushioned, is directly connected to the ram with the help of coupling. Electrode force is varied by means of the air regulator knob.

ELECTRONIC AND ELECTRICAL CONTROL SYSTEM FOR SPOT / PROJECTION

WELDING APPLICATION:

Three different types of controls are available as explained below.

(a) Single timer and Contractor / Thyristor control.

For pedal operated machine, the control will be provided with a weld timer only. When the pedal is depressed the limit switch will operate after the pressure has developed and the weld timer will energies. The weld timer will initiate a heavy duty electromagnetic contractor which energizes the primary of the welding transformer.

For quick response and quality weld, a thyristor switch is used instead of contractor. The weld timer will trigger a heavy duty solid state thyristor switch. The thyristor switch is mounted on an ample water cooled hear sink section to facilitate smooth and efficient current switching to the welding transformer for continuous welding operation without appreciable change in heat sink temperature. For protection of the thyristor switch from voltage transients, thyristors are used.

The thyristor switch firing is controlled by means of a heat control card which varies the phase angle of the voltage to the welding transformer from 5% to 90% Thyristor switch is a better and durable switching device, since there is no moving part as compared to the contractor which has limited contact life.

(b) Sequence Control - For a pneumatic operated machine, the sequence control of squeeze, weld, hold and off will be provided. These timers are fully solid state using the latest in I.C. and transistor technology. The weld timer will energies the thyristor switch as described above.

(C) 1/2 - 9 Cycle Synchronous Control - For accurate and precision welding of components, the control of the welding current is achieved by a precision weld timer of 1/2 - 9 cycles or 99 cycles. This weld timer will energies the thyristor switch as mentioned in

(a). FOR BRAZING APPLICATION - Welding transformer is energized for a longer period by means of a separate brazing switch. Heat control card for smooth change in welding current (5% - 90%) will be provided for optimum brazing.

DIFFERENT STYLES OF APPLICATION

SPOT WELDING

PROJECTION WELDING

ELECTRO BRAZING

- For Automobile equipment, HRC fuse links, Contractor contract, Circuit breakers and many other sheet mental pressed components.

- For Jointing of motor leads, field winding, rotor rings, transformer leads, tungsten carbide tipped tool and many other conductor sections.

WELDTRONIC RANGE OF PRODUCTS : Spot welders, Welding heads, Projection welders, Portable spot welders. Suspension spot welding guns, Tweezers and Capacitor discharge spot welders, Seam welders, Side seam welders, Butt welders and Flash Butt welders. Heating machines for forging. Bolt head hearing machines, Brazing machines, High frequency induction heating machines. Sequence Control panels, Furnace transformers, AC & DC Arc welding machines. Tig and Mig welding machines etc.

Special Features :

- Linear movement of electrodes

- High electrode force - minimum deflection

- Low inertia - rapid follow up

- Aesthetic Looks

- Ergonomically suitable for Indian standards.

- Built as per RWMA -411AS

- Fully adjustable - yet rigid horn

- Easy for quick servicing and adjustment

- Readily accessible

- Convenient for accommodating various types of electrodes for brazing and projection welding.

- User Friendly Electronic Control

- Micro Processor Based Control for precise timing and sequence

- Thyristorised firing panel for Optimum energy delivery

Welding Chart :

| Model | KVA | Maximum thickness in m.m. that can be welded | ||||

| Mild Steel | Stainless Steel | Brass | Aluminium | Nugget dia in m.m. | ||

| USB - 10 | 10 | 2.0 | 1.5 | 1.0 | 0.5 | 7.0 |

| USB - 20 | 20 | 2.5 | 1.8 | 1.2 | 0.6 | 7.5 |

| USB - 30 | 30 | 3.5 | 2.5 | 1.7 | 1.0 | 8.5 |

Technical Specification of Spot Welder :

| Model | BSWM-15 | BSWM -25 | BSWM -30 |

| KVA rating at 50% duty cycle | 15 | 25 | 30 |

| Arm diameter in m.m. | 38 | 38 | 38 |

| Electrode holder diameter in m.m. | 25 | 25 | 25 |

| Throat depth in m.m. | 150/300 | 150/300 | 150/300 |

| Nominal electrode force at 300mm throat in Kg. | 100 | 150 | 200 |

| Max. short circuit current at 300mm throat | 8000 | 12000 | 18000 |

| Insulation class | F | F | F |

| Cooling: Transformer | Air / Water | Air / Water | Air / Water |

| Arms and electrodes | Water | Water | Water |

| Net weight in Kgs. | 80 | 100 | 130 |

| Shipping weight in Kgs. | 120 | 150 | 190 |

| Overall dimensions in Cms H x B x D | 1350x800x700 | 1350x800x700 | 1350x800x700 |

| KVA rating at 50% duty cyclec ASE DIMENSIONS IN CMS H x B x D | 1450x900x800 | 1450x900x800 | 1450x900x800 |

CUSTOMER TO PROVIDE THE FOLLOWING FACILITIES

| Main supply |

| 415 Volts | 1 Phase |

| Main supply cable copper sq.mm. | 6 | 10 | 16 |

| Main disconnection switch | 30 Amps | 30 Amps | 60 Amps |

| Water at maximum temperature of 30oC | 5 LPM | 5 LPM | 10 LPM |

The model USB series is a bench type mounted, medium to heavy duty resistance spot welding cum brazing machine, This can also be used as Projection welder. The machine is designed for a wide variety of production job.